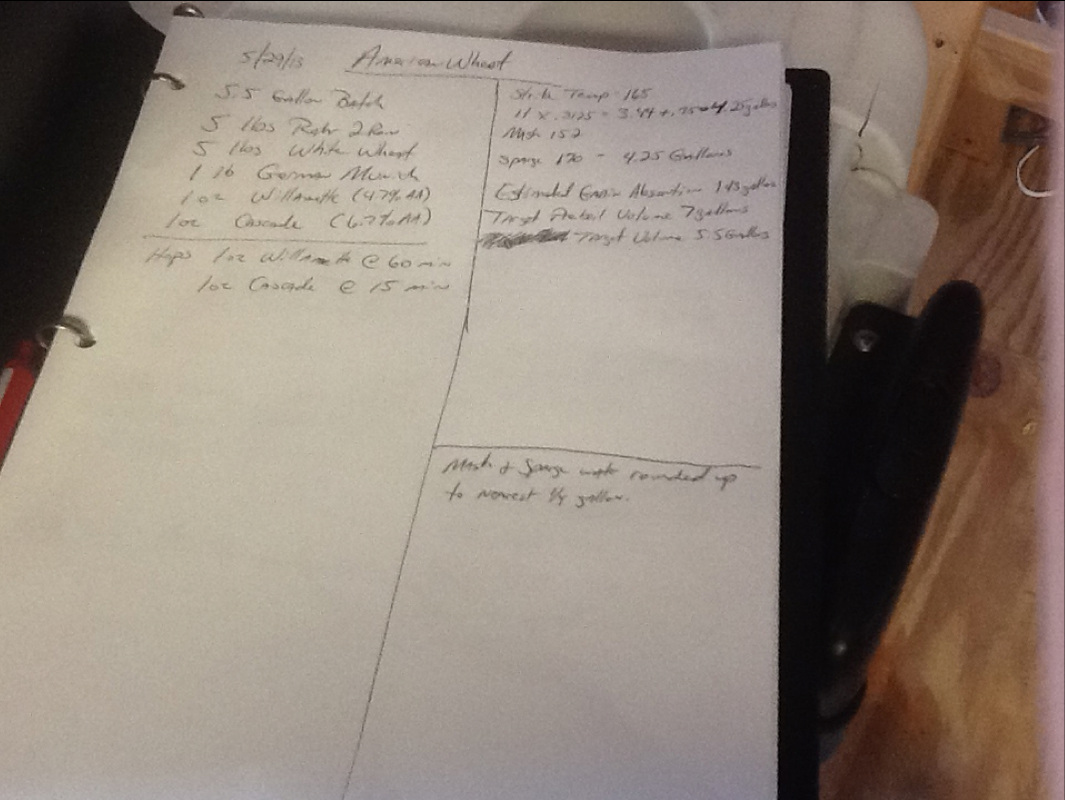

I brewed a version of the first all grain beer that I ever brewed with my friend Dave. We bought the kit from northern brewer back in 2011. I wanted to brew it again but increased the grain and added Munich malt to create a beer similar to Bells Oberon ale.

Filtering the water

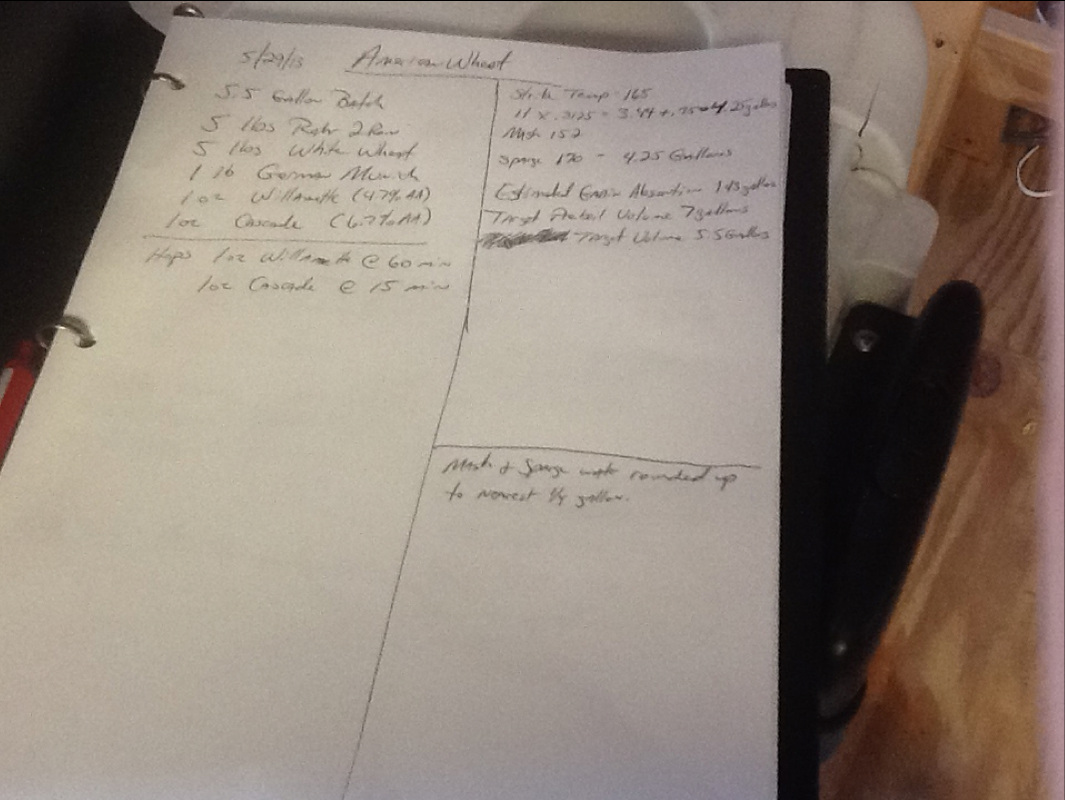

5lbs Rahr 2 row

5lbs white wheat

1lb Munich

Crushing the grains. Thanks to Dave for letting me borrow the barley crusher!

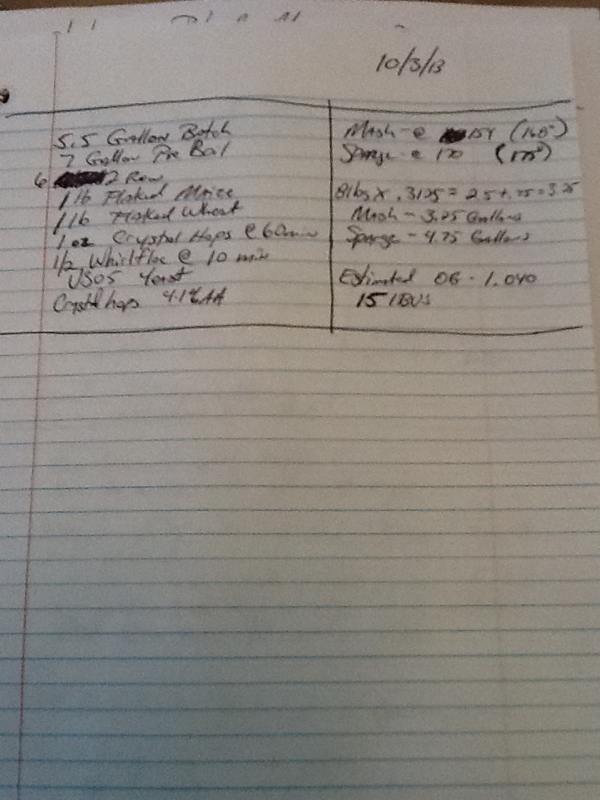

Taking detailed notes

Homebrew!

Mash water

Mash at 152

Mash out. What a nice Caramel color!

1oz willamette at 60 min

1oz cascade at 15 min

Chilling the wort.

My homemade wort chiller. 50 ft of copper.

The wort cooled down in 15 minutes. I transferred to the fermenter. I had to much boil off and ended up with only 4.5 gallons of beer. I was shooting for 5.5. Original gravity is 1.061, a little higher than I wanted.

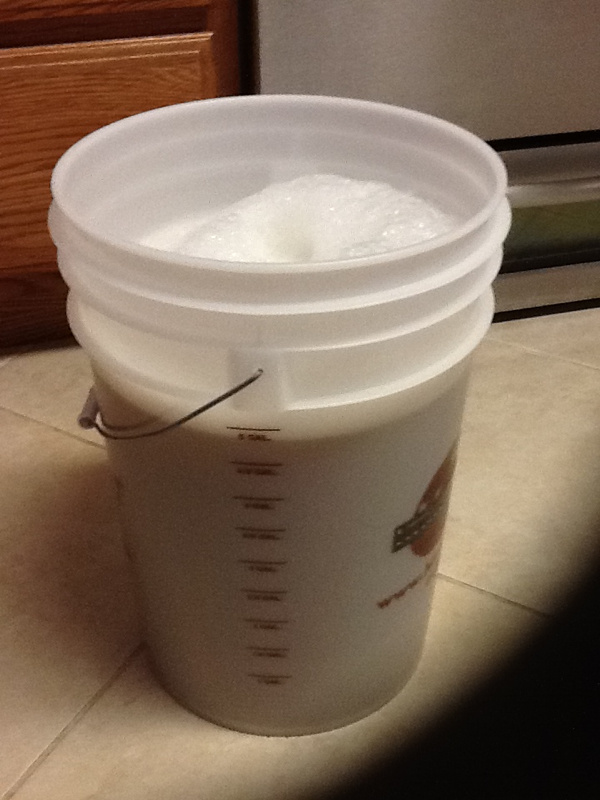

Draining into the fermenter and helping oxygenate the wort! Next pitch the yeast and wait!

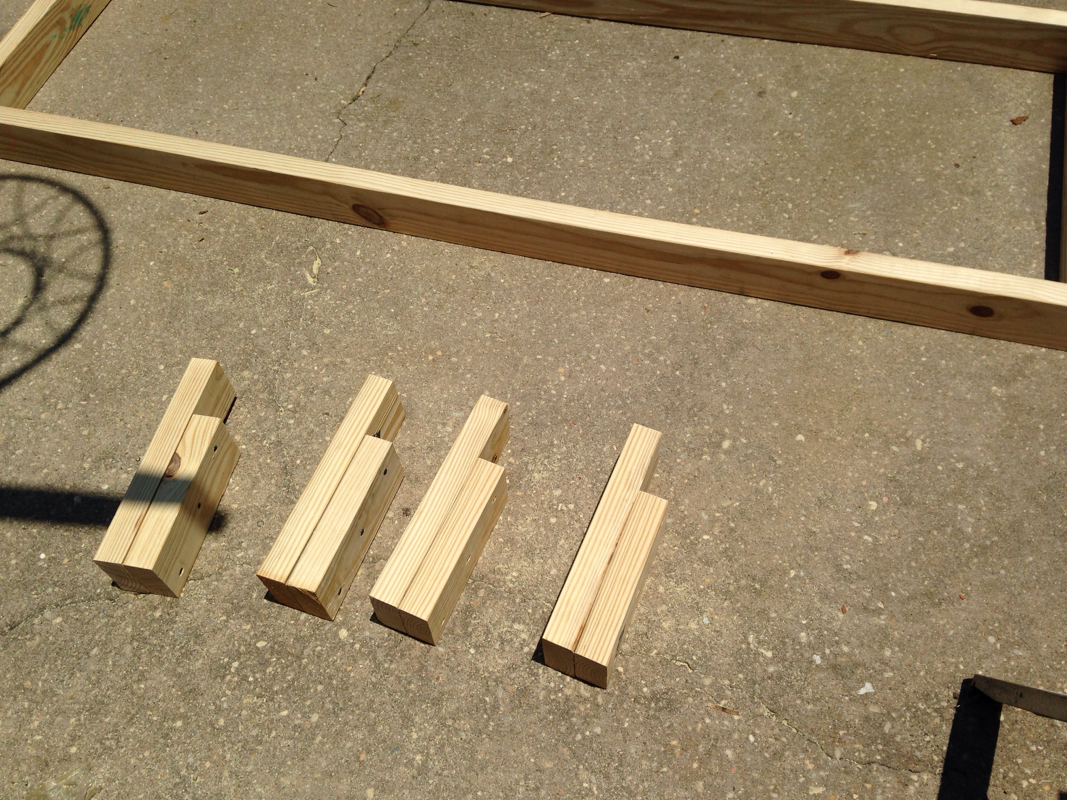

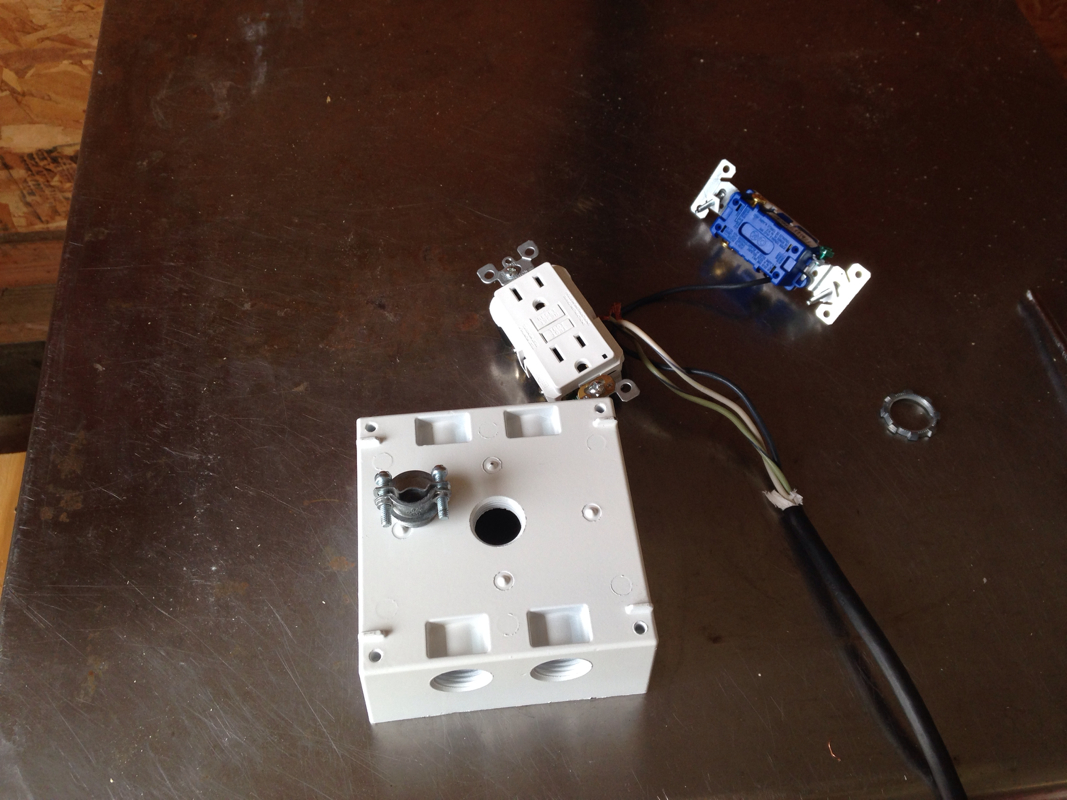

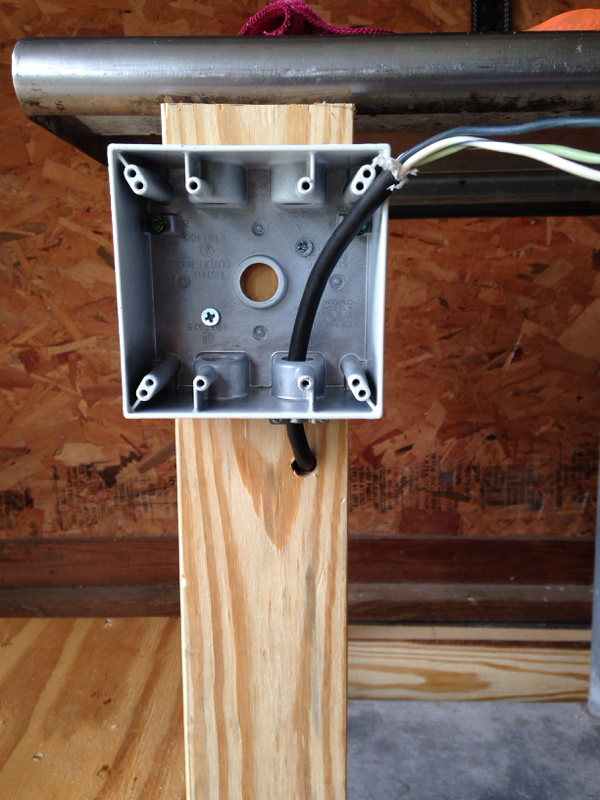

Here are a few pictures of my King Kooker. I used a plywood box to raise the 2nd tier so I could transfer hot water to my mash tun without lifting. I've used it a couple of times and it works great. I also raised the whole cooker so I could put my fermenter under the boil kettle.

This is my 10 gallon, gravity fed brew rig. It is a King Kooker that I bought from amazon last year. I modified it by raising the 2nd tier burner so that I can heat my strike water and transfer it to the mash tun without lifting it or using a pump.

10 gallon brew system

These are pictures from my brew day on 4/4/12. I took step by step pictures to help Mr. Beer brewers convert to All Grain brewing. I used the brew in a bag technique for this brew. In my opinion, it is just as easy as extract brewing and a great way to go to all grain brewing. The best part is that this batch only cost around $8 to make one case of beer!

Grain bill for a Blond Ale

This is my fermenter filled with sanitizer. I use Star San.

I heated a pot filled with 3 gallons of filtered water to 160 degrees

Once the water is the right temperature I add a paint strainer bag. I bought this one a Lowes in the paint department. This will hold the grains.

Slowly add the grains and stir. The grains must be cracked or milled before mashing. You can order grains pre-milled. I use my friends Barley Crusher

Thoroughly stir the grains so none stick together.

Cover the pot to hold in the heat. I mashed at 152 degrees for 1 hour.

I also covered the pot with a towel to hold in the heat. I usually lose 2 degrees in 1 hour.

These are the hops. I used Centennial hops for bittering and Cascade for aroma. Since I am only making a 2 gallon batch, I am using .25 oz of each hops. I have them divided in half so I can add them at different times during the boil.

After 1 hour I pulled the grain bag from the pot and placed in a colander. This allows me to start the boil while all the water drains from the grain bag.

I left the grain bag in the colander for about 15 minutes.

I boiled the wort for 60 minutes. I had 4 hop additions during the boil. I do not use hop sacks. I feel that I get more from the hops if they freely boil with the wort.

I chilled the wort with a wort chiller. I usually use on ice bath in the kitchen sink but I borrowed the chiller from my friend Dave! After the wort is around 68 degrees I put the wort in a sanitized fermenter and place in my fermention fridge. I use a Johnson controller set at 68 degrees and usually ferment from 10 to 14 days. I use Safale US05 yeast. I reused yeast from a pale ale for this batch. More on reusing yeast later.

This is the finished product! Brewed on 4/4/12 Bottled on 4/20/12 and the first taste test on 4/30/12! This beer was fantastic and will be brewed again soon!

RSS Feed

RSS Feed